Selectorized 4 Station Jungle Gym Machine with 4x Weight Stacks (New)

Description

Description

The SFE Commercial 4-Station Jungle Gym is a powerhouse training system designed to deliver multiple exercise modalities in a single, compact unit. Built to support up to four users simultaneously, it’s ideal for strength training, functional fitness, and full-body workouts. Whether for busy commercial gyms or high-end home setups, this multi-station unit maximizes efficiency, versatility, and performance.

Key Features

Multi-User, Multi-Function

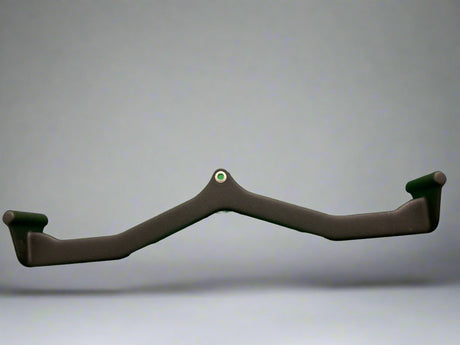

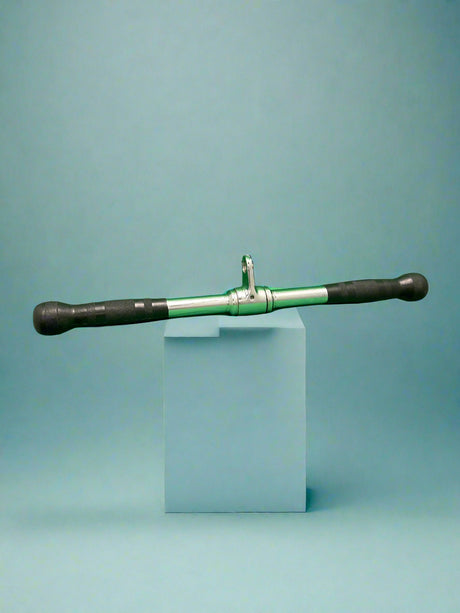

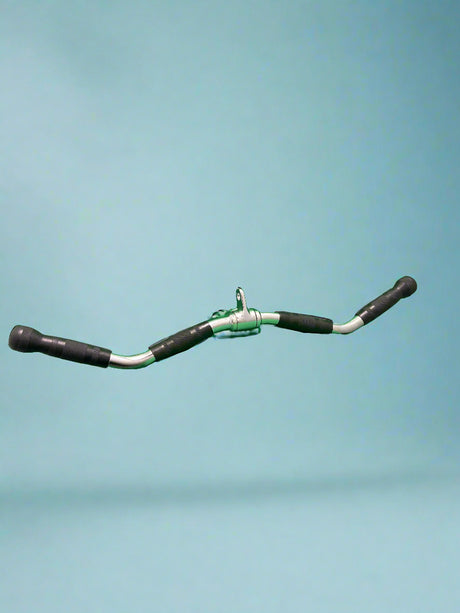

- Four Independent Stations: Lat pulldown, low row, adjustable cables, tricep extension, and more—all accessible at once.

- Full-Body Training: Allows users to train upper body, lower body, and core movements in a single footprint.

Commercial-Grade Construction

- Heavy-Duty Steel Frame: Built for stability and longevity under heavy usage.

- Robust Engineering: Designed to maintain structural integrity even under multiple simultaneous loads.

Smooth, Adjustable Mechanics

- Customizable Attachments & Cable Stations: Adapt to nearly every major movement pattern.

- Precision Cable & Pulley System: Delivers fluid, friction-minimized resistance for joint-friendly motion.

Space-Efficient Design

- Optimized Footprint: Provides multiple workout zones without dominating floor space.

- Modular Layout: Keeps stations organized and accessible for a streamlined training flow.

Specifications

- Assembled Dimensions (W × D × H): 136” × 87” × 92.5”

-

Weight Stack Capacities:

• Low Row: 145 kg / 319 lbs

• Lat Pulldown: 100 kg / 220 lbs

• Adjustable Pulley: 55 kg / 121 lbs

• Tricep Extension: 70 kg / 154 lbs - Warranty: 5 years on frame / 1 year on parts

Why Choose the SFE 4-Station Jungle Gym?

- Efficient and Versatile: Delivers multiple station workouts in one unified system.

- Built for Commercial Use: Engineered to handle heavy loads and frequent usage.

- Simultaneous Training: Ideal for multiple users or circuit-style programming.

- Customizable & Adaptable: Stations and attachments accommodate many exercise variations.

- Durable Investment: With warranty backing and solid construction, it’s designed to last.

The SFE Commercial 4-Station Jungle Gym is the ultimate all-in-one solution for gyms that demand high-performance versatility. With multiple stations, durable construction, and smooth mechanics, it offers a professional-grade training environment suited for any serious fitness space.

Specifications

Specifications

-

Assembled Dimension

-

Pulley Material

-

Steel Guage

-

Weight Stack

-

Pull Ratio

-

Warranty Info

-

Product Weight

-

Shipping Dimensions

FAQ

FAQ

Manufacturing Process

Manufacturing Process

At Sports & Fitness Exchange, we design our frames in-house, cut and form the steel with precision CNC machines, weld every joint using robotic welders for consistency, then clean, coat, assemble, and inspect each unit before it leaves our facility.

SFE's Robotic Welder's at work!

1. Design & Engineering

- Our team starts by designing each piece of equipment to meet commercial gym standards for strength, safety, and ergonomics.

- We model the equipment in CAD software to dial in dimensions, hole spacing, angles, and load paths.

- Every design is reviewed for:

- Structural integrity under heavy loads

- Smooth user experience (range of motion, handle position, etc.)

- Compatibility with common attachments and accessories

2. Precision CNC Cutting & Forming

Once a design is approved, we move into production using CNC (Computer Numerical Control) machines:

- Steel tubes and plates are cut to exact length and shape by CNC equipment.

- Hole patterns (like rack uprights) are drilled or punched with extremely tight tolerances, so:

- J-cups, safeties, and attachments fit cleanly

- Left and right sides line up perfectly

- CNC forming/bending ensures consistent angles and alignment from one unit to the next.

This level of precision is what gives SFE equipment its “everything just fits right” feel.

3. Robotic Welding for Consistency & Strength

After the parts are cut and formed, they move to our robotic welding cells:

- Robotic welders follow the same programmed path on every frame or component, creating:

- Consistent weld penetration

- Even, repeatable bead patterns

- Critical joints and stress points are welded for long-term durability, especially on:

- Uprights and crossmembers

- Base frames

- High-load connection points (e.g., weight stack housings, lever arms)

Using robotic welding reduces variation from piece to piece and helps ensure that your rack is built the same way as a rack in a busy commercial gym. Sports & Fitness Exchange

4. Surface Preparation & Coating

To protect the steel and keep your equipment looking good for years:

- Parts are cleaned and prepped to remove oils, residue, and surface contaminants.

- Components receive a durable, corrosion-resistant finish (such as powder coating), designed to:

- Resist chips and scratches in real-world gym environments

- Stand up to chalk, sweat, and frequent use

Branding elements, labels, and decals are applied after coating where applicable.

5. Final Assembly & Quality Control

In the final stage:

- Hardware, bushings, bearings, pads, rollers, and weight stacks (where applicable) are installed.

- Moving parts are tested for:

- Smooth motion

- Proper alignment

- Noise and friction issues

- Each unit goes through a quality control checklist before it’s cleared to ship.

If it doesn’t meet our standard for commercial use, it doesn’t go out the door.

Why This Manufacturing Process Matters to You

Because of our CNC and robotic welding setup, we’re able to:

- Build commercial-grade equipment that’s suitable for private and boutique gyms

- Maintain tight quality control from raw steel to finished product

- Keep production efficient so we can offer lower prices than many traditional commercial brands Sports & Fitness Exchange

That’s how we’re able to offer heavy-duty racks, rigs, and machines at pricing that works for home gyms, garage gyms, and growing training facilities.

FAQ: SFE Manufacturing

Do you really use the same processes for home-gym equipment as commercial gyms?

Yes. Our SFE-branded equipment is built to commercial standards, which is why it’s popular with private training facilities, boutique gyms, and serious home lifters.

What kind of steel do you use?

We use commercial-grade steel tubing and plate, sized appropriately for the load and application (for example, uprights vs. crossmembers). The exact specs can vary by model, but everything is chosen for long-term durability.

Where is SFE equipment made?

Our SFE manufacturing process is managed through our facility and partners to ensure consistent CNC cutting, robotic welding, and finishing before the equipment ships to you.

Why is SFE equipment more affordable than other commercial brands?

By controlling more of the production process and focusing on efficient manufacturing (like CNC and robotic welding), we can keep costs down without cutting corners on quality

Assembly Info

Assembly Info

SFE machines are heavy-duty, commercial-grade equipment designed for serious training, and they require proper tools and at least two people for assembly.

They arrive in wooden crate on a pallet. Our machines are built for heavy duty use and demand time and effort to set up correctly. We provide detailed assembly manuals for every model, but please be prepared for the process.

Although the majority of our customers are able to assemble the machines themselves, if you are not experienced with equipment that involves bearings, guide rods, weight stacks, and/or heavy frames, we strongly recommend hiring a local fitness equipment technician.

Companies such as Fitness Machine Technicians typically charge $200 to $400 per machine, which can save you 2 to 6+ hours, depending on your tools and experience.

Please note that we do not offer assembly services outside of the Phoenix metro area, as hiring locally is usually faster and more cost-effective, and we prefer to pass those savings on to you!

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.